Mulincan 4-Axle Lowbed Semi-Trailer: A Customized Benchmark for Heavy-Duty Transportation in Africa

Recently, the person in charge of a Nigerian logistics company made a special trip to Mulincan for an on-site inspection regarding the procurement of heavy-duty transportation equipment. After in-depth research on Mulincan’s R&D capabilities, production quality control system, and export service support, the client highly recognized the brand’s comprehensive strength and signed a purchase order for 4-axle 100-ton lowbed semi-trailers on the spot, laying a solid foundation for long-term cooperation between the two parties.

During the inspection, Mulincan’s technical team gave a detailed explanation of the product’s core advantages: from the material selection standard of Q690 high-strength steel plates for the frame and manual precision welding process (adopting CO₂ gas shielded welding, with 100% weld inspection qualification rate and strength highly matching the base material) to the load adaptability design and structural stability verification of the hydraulic gooseneck system. Every detail demonstrated a strict quality control logic. The client stated that Mulincan’s experience in scenario adaptation accumulated over years of developing the African market (such as component protection design for local climates and structural reinforcement solutions adapted to unpaved roads) and the full-process visual management from raw material incoming inspection to finished product delivery truly reflected the reliable quality of “Made in China”.

This 4-axle 100-ton lowbed semi-trailer is a flagship product customized by Mulincan specifically for heavy-duty transportation scenarios in Africa, with its core design deeply matching local operating conditions:

1、Heavy-Duty Structure: Solid Foundation for Load-Bearing

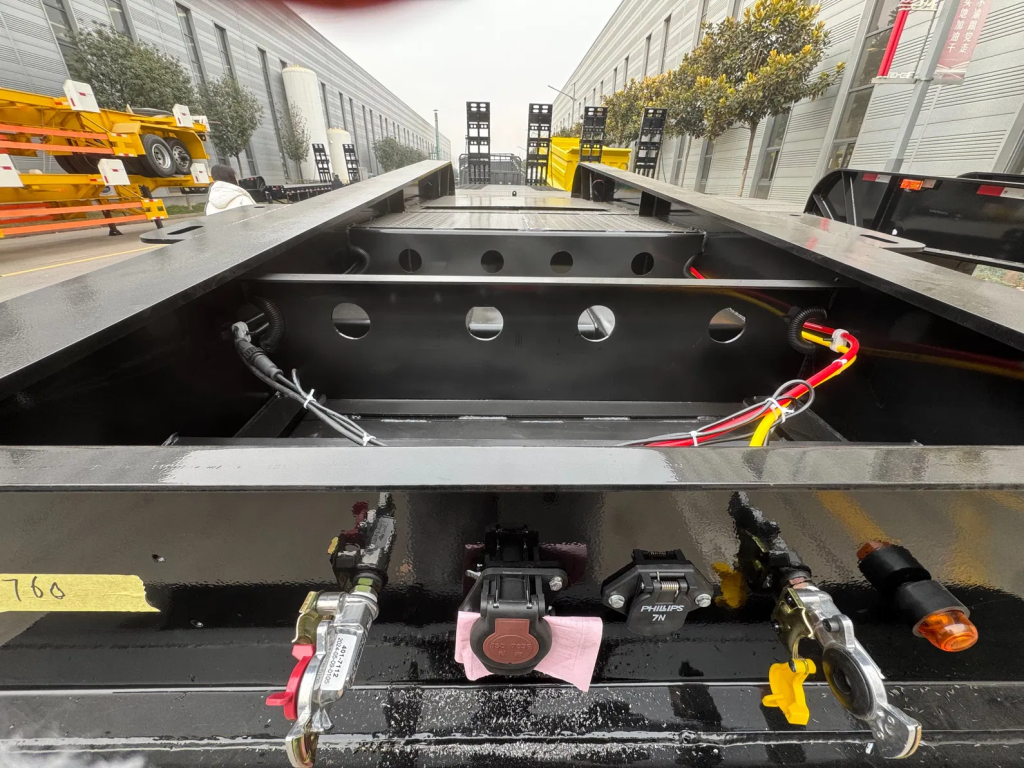

The frame is fabricated by segmental welding of Q690 high-strength steel plates (the main beams and crossbeams are connected via full welding process, with weld spacing controlled within 50mm). Combined with reinforced crossbeams with a dense spacing of 500mm, the overall torsional strength is 40% higher than that of ordinary models. Equipped with a hydraulic gooseneck system, it can flexibly adjust the gooseneck height via hydraulic control to match different types of tractors. Together with the 4-axle balanced load-bearing design (with a rated load of 25 tons per axle), it can evenly distribute the 100-ton heavy load to each load-bearing structure. Even during high-frequency transportation of heavy machinery on unpaved roads in Africa, it can effectively disperse stress and prevent frame deformation, ensuring stable long-term use.

2、Road Condition Adaptation: Enhanced Key Components

Multiple customized optimizations have been made to address the rough dirt roads, gravel roads, and high-temperature environment in Africa: it is equipped with 14.00R25 reinforced wear-resistant tires, with tire treads made of high-silicon formula and deepened patterns (depth up to 18mm), providing 30% better grip than ordinary tires. Meanwhile, the tire sidewalls are added with anti-scratch rubber layers, extending durability by 40%. The braking system adopts a high-temperature adaptive design; through a special heat dissipation structure, it can maintain continuous braking without failure in high-temperature environments above 40℃. Additionally, the brake shoes are made of ceramic wear-resistant material, extending the replacement cycle to 1.5 times that of traditional products.

3、Efficient and Compliant: Improved Loading/Unloading Efficiency

Adopting a 950mm low-deck design, the total cargo height can be controlled within the 3.8-4.0m road height limit in most African countries, eliminating the need for applying for special traffic permits and reducing transportation delays. Equipped with a hydraulically foldable rear ramp (maximum load capacity of 80 tons), heavy equipment such as excavators and crawler cranes can drive directly onto the deck. The loading/unloading time for a single piece of equipment is shortened to within 30 minutes, which is 50% more efficient than traditional trailers, making it suitable for high-frequency construction site transportation needs.

4、Stable Handling: Reduced Maintenance Costs

The center of gravity distribution of the vehicle body is optimized through finite element analysis. Despite a rated load of 100 tons and an overall length of 16 meters, its center of gravity is 12% lower than that of similar products. When driving on narrow rural curves and temporary construction site passages, its handling flexibility is significantly better than that of other 4-axle semi-trailers of the same class. Key components of the entire vehicle (such as axle bearings and hydraulic seals) are selected from well-known international brands. Combined with hot-dip galvanizing anti-rust treatment on key parts, it effectively resists moisture and rust during the African rainy season, extending the service life to over 8 years and reducing annual maintenance costs by 30%.

As a core export product in Mulincan’s heavy-duty trailer series, lowbed semi-trailers have covered more than 20 African countries including Nigeria, Ghana, Tanzania, and Zambia, and are widely used in infrastructure construction, mining, and industrial equipment transportation. Relying on “scenario-based customized” product design and comprehensive export services (such as providing detailed maintenance manuals, supporting remote technical guidance, and ensuring timely supply of spare parts), Mulincan’s lowbed semi-trailers have become a “trusted choice” in the African logistics sector.

The successful signing of this 4-axle 100-ton lowbed semi-trailer not only accurately meets the Nigerian client’s needs for cross-regional transportation of heavy equipment but also confirms Mulincan’s technical accumulation and market insight in the heavy-duty logistics equipment field, continuously injecting strong momentum into “Made in China” to further develop the African market.